High-Power Fiber Collimators: The “Gatekeepers” of LiDAR Systems

With the widespread application of LiDAR technology in fields such as autonomous driving, aerospace, and intelligent robotics, the key technologies of LiDAR systems have gradually become a focus of industry attention. High-power fiber collimators, as the “gatekeepers” of LiDAR systems, play a crucial role in ensuring the collimation, stability, and high efficiency of the laser beam. This article will delve into the working principle, technical challenges, and applications of high-power fiber collimators in LiDAR systems.

I. What is a High-Power Fiber Collimator?

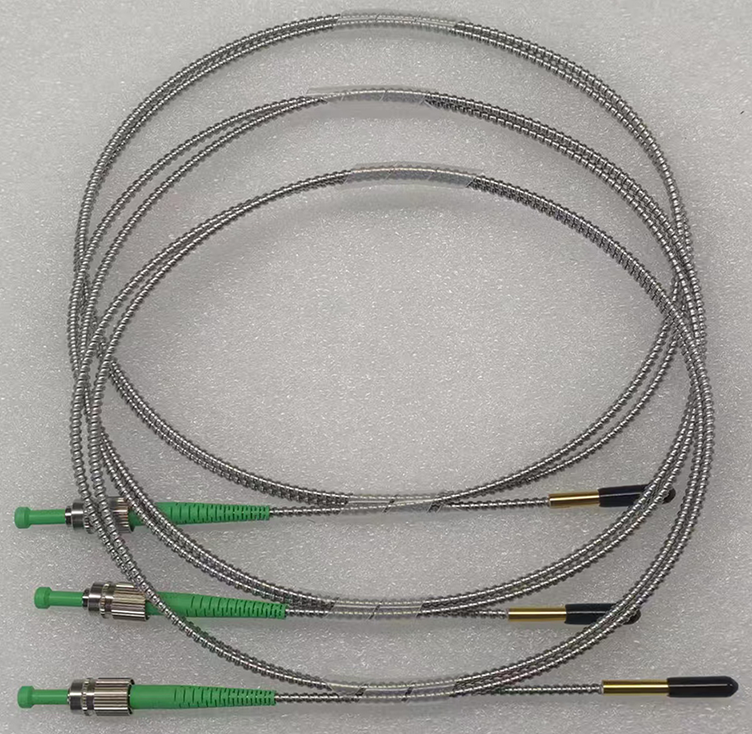

A high-power fiber collimator is an optical device capable of collimating a laser beam output from an optical fiber (i.e., making the laser beam direction parallel and focused on the target position). It typically consists of multiple optical elements, such as optical fibers, lenses, and mirrors, designed to effectively transmit the laser energy transmitted in the fiber to the target area, ensuring the quality and power output of the laser beam.

In a LiDAR (LiDAR) system, the emitted laser beam is transmitted through optical fiber to a fiber optic collimator. The collimator then converts the beam into a uniformly oriented and energy-efficient laser beam, ensuring high-precision ranging and environmental scanning.

II. Working Principle of a High-Power Fiber Collimator

The working principle of a high-power fiber optic collimator is based on optical imaging and beam transmission principles. Its core function is to process the laser beam output from the fiber optic cable using optical elements, converting it into an ideal parallel beam and focusing or expanding it as needed.

Fiber Optic Laser Source Output: The laser signal generated by the laser is transmitted to the collimator through optical fiber.

Fiber Optic-Collimator Interface: The end of the fiber optic cable is typically equipped with a specific optical interface. The collimator performs initial optical adjustment on the incoming light signal.

Lens and Mirrors: The collimator is typically equipped with high-precision lenses and mirrors to further adjust the direction and shape of the beam, ensuring that the output laser beam has uniform energy and consistent direction.

Laser Beam Output: After collimation, the laser beam output can accurately illuminate the predetermined target area, achieving effective scanning and ranging.

III. Technical Challenges of High-Power Fiber Collimators

In high-power lidar systems, high-power fiber collimators must face a series of technical challenges:

High-Power Transmission Capability: With the increasing power demands of lidar systems, ensuring stable operation of the fiber collimator under high power conditions and preventing optical component failure due to overheating or optical damage is a key issue in designing high-power fiber collimators. Typically, high-temperature resistant and radiation-resistant materials are needed to manufacture the optical components, and their heat dissipation design must be optimized.

Accuracy and Stability: The fiber collimator needs to maintain beam stability and accuracy during long-term operation. Any minute deviation can affect the ranging accuracy of the lidar and even lead to system failure. Therefore, the optical components of the fiber collimator need to possess extremely high precision and stability to prevent beam deviation caused by external factors such as temperature changes and mechanical vibrations.

Size and Weight Optimization: In some applications, such as autonomous vehicles or drones, there are stringent requirements for the size and weight of LiDAR systems. High-power fiber collimators must balance high performance and miniaturization to adapt to these application scenarios.

Beam Quality Control: High-power laser beams are prone to beam diffusion and energy loss during collimation. Maintaining high-quality laser beam output and avoiding beam distortion during collimation is another challenge. Efficient optical design and optimized optical component configuration are crucial for ensuring beam quality.

IV. Application of High-Power Fiber Collimators in LiDAR

In LiDAR systems, laser beam emission is one of the core tasks, and high-power fiber collimators are a key component in the laser beam emission system. Their applications in LiDAR are mainly reflected in the following aspects:

High-Precision Ranging: The core function of LiDAR is to measure the distance between the laser beam and the target. The collimation and stability of the beam directly affect the ranging accuracy. High-power fiber collimators can ensure the quality of the laser beam, enabling LiDAR to accurately measure targets at long distances.

Wide-Area Environmental Scanning: LiDAR is not only used for ranging but can also perform 3D scanning of the surrounding environment by rotating or emitting laser beams at multiple angles. High-power fiber optic collimators provide a stable and powerful laser beam, ensuring that LiDAR can scan distant objects and obtain accurate distance information in complex environments.

Real-Time Data Acquisition: In applications such as autonomous driving and industrial inspection, LiDAR requires real-time acquisition of high-quality data about the surrounding environment. High-power fiber optic collimators support the rapid scanning capability of LiDAR by providing a high-power and stable beam, ensuring that the system can respond to external changes in real time.

Interference Resistance: The beam output intensity of high-power fiber optic collimators is sufficient to penetrate some environmental interference, such as fog, rain, and snow, thus maintaining good performance in complex environments. This is particularly important in the field of autonomous driving, as autonomous vehicles must be able to operate efficiently and safely under various adverse weather conditions.

V. Future Development Directions

With the continuous development of LiDAR technology and the expansion of application scenarios, the technology of high-power fiber optic collimators is also constantly advancing. Future high-power fiber optic collimators are likely to evolve in the following directions:

Integration and Miniaturization: High-power fiber optic collimators will further develop towards integration and miniaturization, especially in fields such as autonomous vehicles where size and weight are critical. High integration and compact design will become important research directions.

Enhanced Interference Immunity: With increasing environmental complexity, high-power fiber optic collimators need further improvements in interference immunity to ensure stable operation under harsher conditions. For example, optimizing beam control through intelligent algorithms can improve their adaptability to factors such as rain, snow, and fog.

High Efficiency and Low Cost: With increasing market demand for lidar, reducing the production cost of high-power fiber optic collimators and improving their manufacturing efficiency will be important future research directions.

Higher Power Handling Capacity: As lidar power requirements increase, future fiber optic collimators will need higher power handling capabilities while maintaining an efficient thermal management system to prevent damage to optical components due to excessive power.

VI. Conclusion

High-power fiber optic collimators, as a key component in lidar transmitting systems, bear the important task of beam collimation and stable output. With the continuous advancement of lidar technology and the increasing application demands, high-power fiber optic collimators will face more technical challenges and innovation opportunities. It is believed that in future technological evolution, high-power fiber optic collimators will, with greater efficiency, stability, and intelligence, help lidar play a greater role in various fields.

Comments are closed