How to Select a 1064nm High-Power Fiber Collimator? Key Parameters and Selection Guide

In the realms of fiber lasers, material processing, LiDAR, and cutting-edge scientific research, the 1064nm wavelength has become the preferred choice for numerous high-power applications due to its excellent transmission characteristics within the atmospheric window and the maturity of high-power fiber laser technology. The fiber collimator—a critical component that converts divergent light from an optical fiber into parallel spatial light—has a selection process that directly impacts the efficiency, beam quality, and long-term reliability of the entire system.

When power levels escalate from a few watts to hundreds of watts, or even kilowatts, the logic behind collimator selection undergoes a fundamental shift. This article, based on product specifications from mainstream manufacturers and failure mechanisms under high-power environments, outlines a clear, step-by-step decision-making framework.

I. Core Parameters: The Decisive Difference Between “Functional” and “Optimal”

For low-power collimators (milliwatt to several-watt range), the selection process is relatively simple, primarily focusing on insertion loss and working distance. However, in high-power scenarios, thermal management capability and beam quality preservation become the decisive factors.

1. Power Handling Capability and Thermal Management Solutions

This is the primary differentiator for high-power collimators. According to available data, the power levels for 1064nm collimators form a clear hierarchy:

-

Conventional Low Power: 0.3W, 1W, 5W

-

Medium-High Power: 20W, 50W, 200W

-

Ultra-High Power: 500W, 1000W (Typically requires large beam diameter and cooling solutions)

Selection Advice:

-

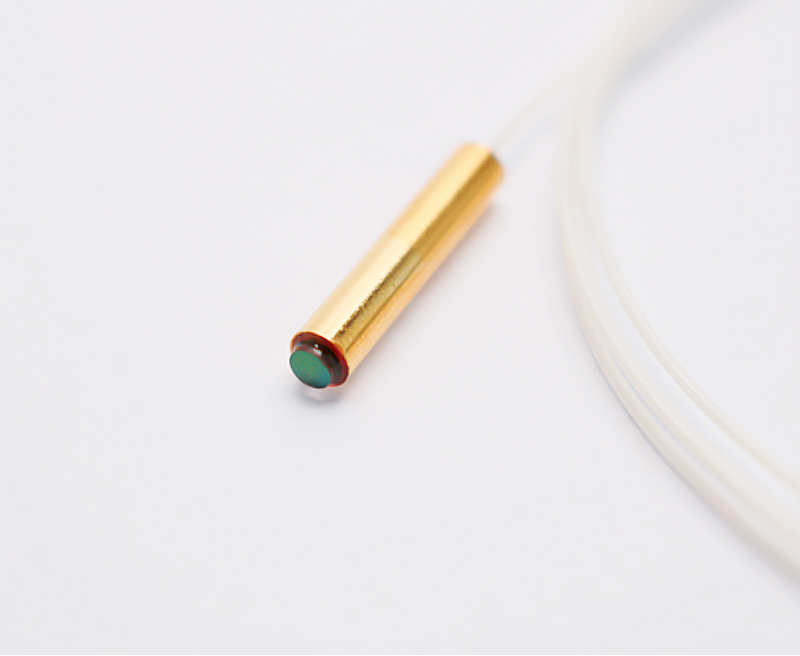

< 20W: Passive heat dissipation via the metal housing (e.g., gold-plated or glass tubes) is usually sufficient; no additional cooling required.

-

20W – 200W: This range marks the critical zone where thermal lensing effects begin to manifest. R&D from companies like Advanced Fiber Resources indicates that the 200W level represents a key technical hurdle for mitigating thermal lensing. Priority should be given to manufacturers who have optimized heat distribution through specialized bonding processes, low-refractive-index epoxy, or structural design.

-

≥ 200W: Air cooling or water cooling options become mandatory. For instance, some 1000W-class collimators explicitly require water cooling (e.g., flow rate 1.5-3 L/min, water pressure 8 Bar). Without active cooling, even if the collimator itself doesn’t fail, the beam distortion caused by thermal lensing will render the system ineffective.

2. Output Beam Diameter and Working Distance

A larger beam diameter is not always better; it must be considered in conjunction with the working distance (WD).

-

Physical Relationship: For a fixed working distance, a larger beam diameter results in a smaller far-field divergence angle (approximately inverse relationship).

-

Application Scenarios:

-

Short Distance / High Energy Density (e.g., laser marking, cutting): Typically choose small beam diameters from 0.4mm to 3.5mm, with working distances of 5-50mm.

-

Long Distance / Wide Area (e.g., LiDAR, remote sensing): Requires large beam diameters of 6mm to 12mm to suppress divergence, with working distances potentially reaching hundreds of millimeters or even 1 meter.

-

Important Pitfall: Some manufacturers’ stated “working distance” refers to the distance from the collimator end face to the minimum beam waist of the focused spot, while others define it as the “collimation range.” Always verify the test distance for the specified beam diameter (e.g., “5-1000mm from output surface”) to avoid premature beam divergence in long-distance applications.

3. Insertion Loss and Return Loss

-

Insertion Loss (IL): Typical insertion loss for high-power collimators ranges from 0.2 to 0.5dB. For systems operating at hundreds of watts or more, a 0.1dB difference in loss translates to several watts or even tens of watts of deposited heat. The Transmission Efficiency metric is often more intuitive than the dB value; high-quality, high-power collimators can achieve transmission efficiencies of 97%-98%.

-

Return Loss (RL): In high-power systems, back-reflected light poses a significant risk of burning out the front-end laser source. RL ≥ 50dB is the industry safety baseline. FC/APC (Angled Physical Contact) connectors are mandatory for all high-power applications. Mistakenly using FC/PC (Physical Contact) connectors can cause a sudden drop in return loss by over 5dB, creating a serious safety hazard.

4. Beam Quality Evaluation Metrics

-

Ellipticity/Circularity: High-power processing typically demands beam circularity > 92%. Significant ellipticity often indicates stress within the lens assembly or alignment errors.

-

Divergence Angle: Determines the effective operational range of the system. For example, a 12mm large-beam collimator can achieve a full-angle divergence as low as 0.3mrad.

-

Beam Pointing Accuracy: Crucial for high-precision interferometry or coupling applications. Typically requires < 1°, often < 0.5°.

II. Advanced Dimensions: Polarization, Fiber, and Packaging

1. Polarization-Maintaining (PM) vs. Non-Polarization-Maintaining (SM)

-

When to Choose PM: If your laser source outputs through PM fiber and the subsequent system requires maintaining a linear polarization state (e.g., for nonlinear frequency conversion, coherent detection), a PM980-type PM collimator is mandatory. Pay attention to the extinction ratio (typically > 23dB) and slow axis alignment.

-

When to Choose Non-PM: The vast majority of laser processing applications (cutting, welding, hardening) are polarization-insensitive. Choosing Hi1060 or LMA (Large Mode Area) fiber types is sufficient and more cost-effective.

2. Fiber Type and Connector

-

Fiber Matching: Must match the output fiber of the upstream laser source. Common 1064nm single-mode or PM fibers are PM980 or Hi1060.

-

Cable Jacket: For applications involving frequent movement of high-power equipment (e.g., robotic arms), 3mm armored cable is recommended for enhanced tensile and crush resistance. For fixed benchtop experiments, 900um loose tube or bare fiber may be suitable.

-

Connector Insertion Loss: Note that product specifications often exclude connector loss. Adding one pair of FC/APC connectors increases insertion loss by approximately 0.3dB and reduces return loss by 5dB.

3. Evaluating Specialized Processes

The manufacturing challenge for high-power collimators lies in adhesive/handling. Ordinary collimators use standard epoxy, and adhesive carbonization under high power is a primary failure mode. Patented techniques involve using epoxy with a refractive index lower than the fiber cladding to secure double-clad fibers. This effectively strips away cladding light, preventing end-face overheating and damage. When selecting, inquire if the manufacturer performs “adhesive degassing” or “cladding light stripping” specifically for high-power applications.

III. Selection Process: A Four-Step Decision Method

Step 1: Determine the Power Threshold and Lock in the Cooling Architecture

-

P ≤ 20W: Passive cooling, standard series.

-

20W < P < 200W: Requires industrial-grade high-power series; scrutinize thermal lensing performance metrics.

-

P ≥ 200W: Must select air-cooled/water-cooled versions; verify cooling medium parameters.

Step 2: Based on Optical Requirements, Calculate Beam Size and Working Distance

-

Define the required transmission distance after collimation.

-

Define the target beam diameter or acceptable divergence angle.

-

Match requirements with the manufacturer’s product matrix (e.g., “12mm beam @ 0.3mrad” suitable for long range; “3.5mm beam @ 1mrad” suitable for general processing).

Step 3: Verify Fiber Interface and Environment

-

Check fiber type compatibility (mode field diameter, numerical aperture).

-

Mandatory verification of connector type: FC/APC.

-

Check cable jacket type (moving: armored / fixed: loose tube).

Step 4: Scrutinize Non-Standard Customization Boundaries

-

Is vacuum compatibility required? (Standard collimators use adhesives that outgas, making them incompatible with vacuum).

-

Is an extended operating temperature range needed? (Standard -5~70°C; custom solutions required for expansion).

-

Is high peak power pulse handling required? (Verify peak power rating, typically up to 10-20kW).

Conclusion

Selecting a 1064nm high-power fiber collimator essentially involves finding the optimal balance between thermal management, beam profile characteristics, and mechanical reliability. For applications below 20W, standardized products from major manufacturers are sufficiently mature. However, when power surpasses the hundred-watt level, thermal management solutions (water cooling/air cooling/structural heat dissipation) and damage-resistant coatings/bonding processes should become the primary investigation priorities, rather than merely comparing insertion loss values.

Comments are closed