What is a High-Power Fiber Collimator? How does it differ from a regular collimator?

I. Overview

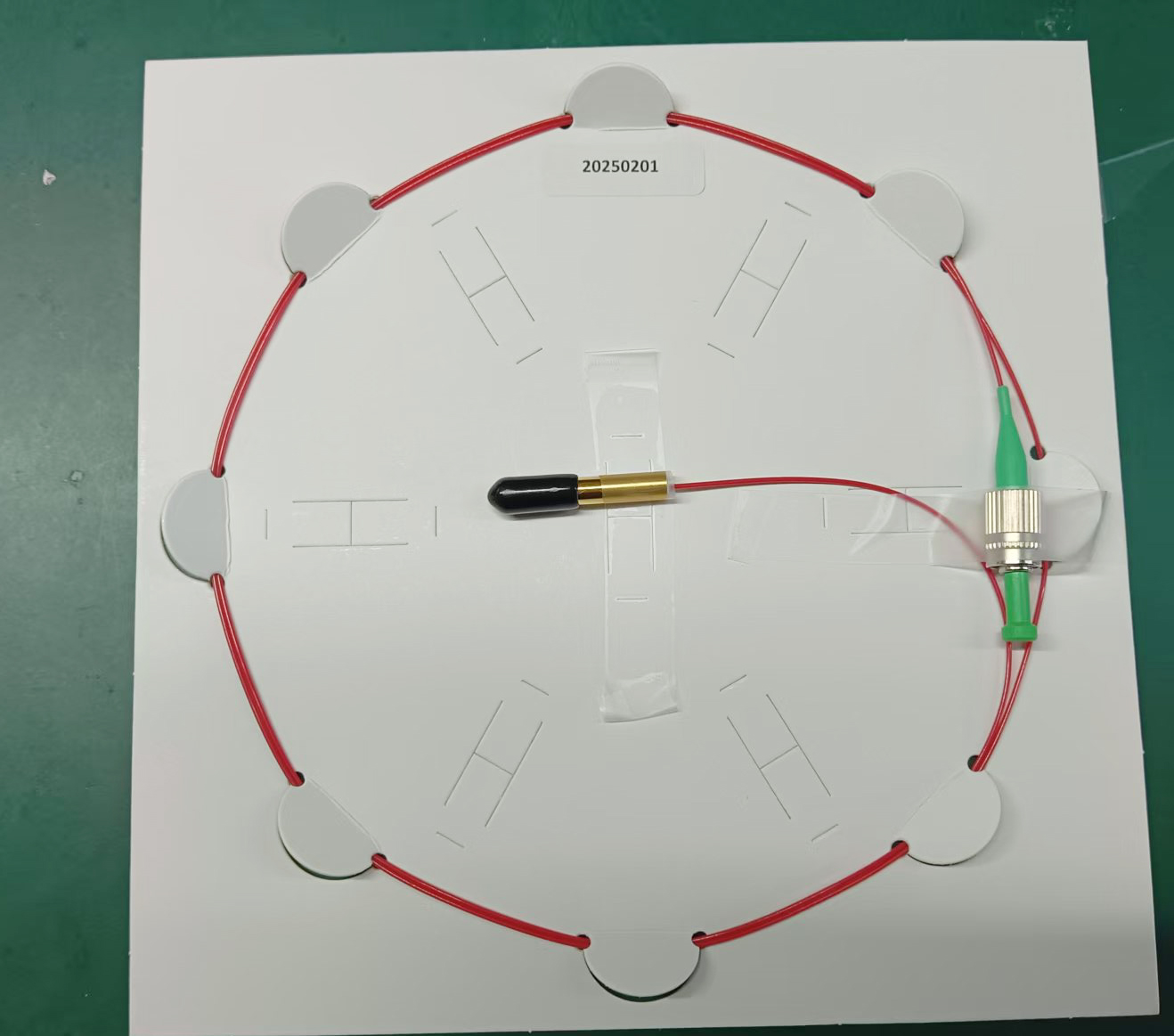

High-power fiber collimator is an optical device that efficiently and stably couples high-power laser light from an optical fiber into free space, forming a low-divergence collimated beam. It is a critical passive component in high-power laser systems, serving as a bridge between two light transmission modes: “fiber” and “free space.”

Compared to ordinary fiber collimators, high-power models are comprehensively optimized in design, materials, and manufacturing processes to address the severe challenges posed by high-power lasers, such as thermal effects, nonlinear effects, and power damage thresholds.

II. Core Features

- Ultra-High Power Handling Capability:

High Damage Threshold Optical Components: Uses specially coated lenses (such as fused silica or sapphire lenses), whose coatings and substrates can withstand extremely high power densities (typically hundreds to thousands of watts of continuous light, or even higher peak pulse power).

Low Absorption Materials: All optical materials (lenses, adhesives, fiber end caps) are carefully selected for their extremely low optical absorption rate to minimize heat accumulation. - Excellent Thermal Management Capability:

Active/Passive Heat Dissipation Design: Typically equipped with a metal heat sink housing, and even integrated water cooling or TEC temperature control modules, to quickly dissipate heat generated inside the device and maintain stable optical performance.

Adhesive-Free or High-Temperature Adhesive Bonding: Uses laser welding, optical contact (optical adhesive), or high-temperature UV/thermally cured adhesives to fix optical components, avoiding the failure or carbonization of traditional adhesives at high temperatures. - High Beam Quality and Stability:

Low Wavefront Distortion: Lenses are precisely machined and surface-optimized to ensure high wavefront quality of the output beam (low aberrations), which is crucial for subsequent focusing and material processing quality.

High Pointing Stability: A robust mechanical structure and thermally stable design ensure that the beam pointing and spot position remain stable during long-term operation or changes in ambient temperature. - Low Insertion Loss and High Return Loss:

High-Efficiency Anti-Reflection Coating: The lens surface is coated with a broadband anti-reflection coating to maximize transmittance (typically >99.5%) and reduce reflection loss. Anti-reflection Design: Effective suppression of back-reflection is achieved through angled lens mounting or angled polishing of the fiber end face (APC), protecting upstream lasers (especially semiconductor lasers) from reflected light interference. - Reliable Packaging and Fiber Interface:

Industrial-grade robust packaging: Utilizes stainless steel or copper-aluminum alloy housings, providing excellent shock resistance and dust protection.

Standard fiber interface: Typically compatible with high-power standard connectors such as QBH, QD, and D80, ensuring reliable and safe connection with high-power fiber lasers.

III. Main Application Areas

High-power fiber collimators are the cornerstone of high-energy laser systems in industrial, scientific research, and defense fields. Main applications include:

- Industrial Laser Processing:

Laser cutting/welding/cladding: As a front-end component of the fiber laser output head, guiding the laser to the galvanometer scanning system or direct focusing head.

Additive manufacturing (3D printing): Used in metal 3D printing (SLM) to guide high-power lasers to the powder bed. - LiDAR and Ranging:

Used in long-range, high-precision vehicle-mounted LiDAR, topographic mapping, and space exploration systems to emit high-power detection laser beams. - Scientific Research:

Nonlinear optical frequency conversion: Coupling high-power fiber lasers into crystals (such as LBO, BBO) for frequency doubling, sum-frequency generation, etc., to produce lasers of new wavelengths.

Laser-plasma interaction: Used in strong-field physics experiments to guide and shape ultra-high-power pulsed lasers.

Gravitational wave detection: Used for beam expansion and collimation in interferometers. - Defense and Security:

Laser directed energy weapons: As part of the beam control and emission system.

Optoelectronic countermeasures and illumination: Used for high-brightness illumination, dazzling, or interference. - Medical Equipment:

In some high-power surgical laser treatment equipment, used to guide the laser to the surgical site. - Beam Combining:

In spectral combining or coherent combining techniques, used to collimate and align the beams of multiple high-power fiber lasers to synthesize a single higher-power laser beam.

III. Summary

High-power fiber collimators are far more than simple lenses and fibers; they are high-tech products integrating high-precision optics, advanced materials science, precision mechanics, and efficient thermal management. Its performance directly determines the upper limit of the output power, long-term stability, and ultimate application effect of the entire high-power laser system. As the power of fiber lasers continues to increase, the requirements for their front-end collimators are becoming increasingly stringent, driving the technology to continuously develop towards higher power, better beam quality, and stronger environmental adaptability.

Comments are closed