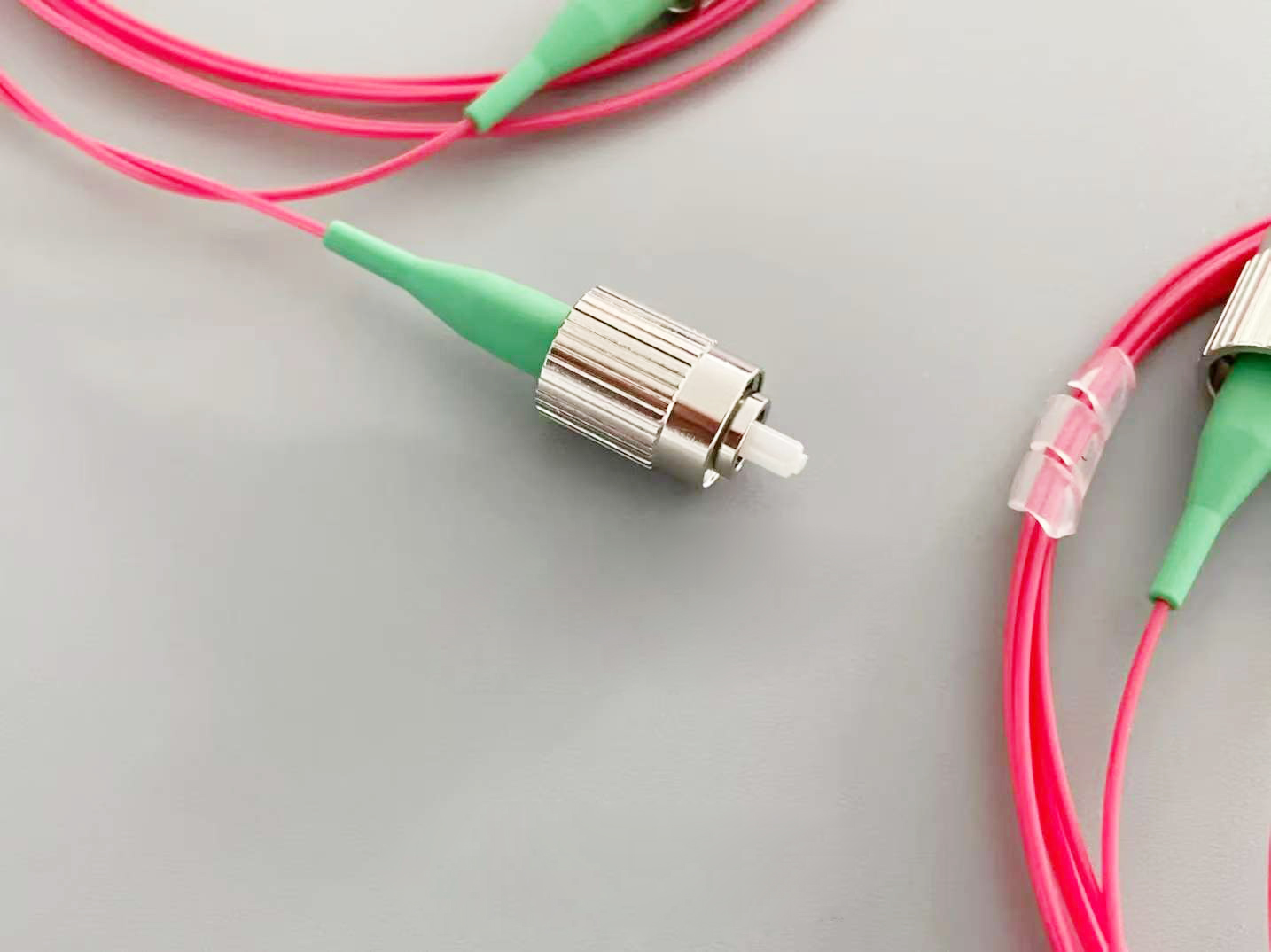

Application of Fiber Endface Processing Technology in Low-Loss Optical Devices

In modern optical communication, sensing, and laser systems, insertion loss is one of the key indicators used to evaluate the performance of optical devices. The quality of fiber endface processing directly determines the transmission efficiency and long-term stability of optical signals. High-quality endface treatment not only minimizes insertion and reflection losses but also enhances device reliability. This article discusses the critical role and practical application of fiber endface processing technology in the manufacturing of low-loss optical devices.

1. Influence of Fiber Endface on Optical Performance

The fiber endface serves as the key interface for light transmission and coupling. An ideal endface should have the following characteristics:

-

Flat and defect-free surface: Prevents scattering loss and mode distortion.

-

High perpendicularity: Ensures precise optical axis alignment to minimize insertion loss.

-

Clean and contamination-free surface: Avoids scattering or absorption caused by dust and residue.

-

Controlled reflectivity: Reduces Fresnel reflection and back reflection that affect signal stability.

Any imperfections—such as scratches, cracks, contamination, or angular deviation—can cause significant optical power loss or even device failure.

2. Common Fiber Endface Processing Techniques

(1) Precision Cleaving and Polishing

Accurate fiber cleaving and multi-step polishing are essential for achieving smooth, defect-free endfaces. The combination of coarse grinding, fine polishing, and final buffing ensures submicron surface roughness.

Key points:

-

Coarse grinding removes surface damage from cleaving.

-

Fine polishing refines the geometry and smoothness.

-

Controlled pressure and time during final polishing prevent over-polishing or deformation.

(2) Laser Endface Processing

Laser-based endface reshaping provides a non-contact, precise solution for high-power fiber devices. Laser melting can repair microcracks and improve surface smoothness.

Advantages:

-

Eliminates mechanical stress and contact damage.

-

Provides high repeatability and control accuracy.

-

Suitable for high-power fiber collimators and laser device interfaces.

(3) Chemical Etching and Plasma Cleaning

Chemical etching removes micro-defects and stress layers, while plasma cleaning effectively eliminates organic residues and microscopic particles.

Benefits:

-

Greatly improves endface cleanliness.

-

Reduces return loss (RL).

-

Enhances coating adhesion and long-term stability.

(4) Endface Coating Technology

To further reduce reflection losses, Anti-Reflection (AR) or High-Reflection (HR) coatings are commonly applied to fiber endfaces.

Typical applications:

-

AR coatings improve transmission efficiency in low-loss optical switches, collimators, and circulators.

-

HR coatings are used in laser systems to enhance reflective output and optical feedback control.

3. Application in Low-Loss Optical Devices

-

Fiber Collimators

High-precision polishing combined with AR coating can reduce insertion loss to below 0.2 dB, significantly improving coupling efficiency. -

Optical Switches and Circulators

Consistent endface quality ensures stable and repeatable signal transmission during optical path switching, maintaining low loss across multiple channels. -

High-Power Fiber Components

In high-power operation, minor surface defects can lead to thermal accumulation and damage. Laser reshaping and advanced coating techniques greatly enhance power handling and thermal reliability.

4. Future Development Trends

With the rapid evolution of photonic integration and precision manufacturing, fiber endface processing is moving toward automation, intelligent control, and nanometer-level precision. The integration of AI-based visual inspection, ultrafast laser processing, and adaptive polishing will further improve consistency and throughput, supporting large-scale production of ultra-low-loss optical components.

5. Conclusion

Fiber endface processing is a critical step in achieving low-loss, high-performance optical devices. Through advanced techniques such as precision polishing, laser reshaping, and optimized coating, both insertion and reflection losses can be significantly reduced. For modern optical communication, laser, and sensing systems, superior endface quality represents not only high performance but also long-term reliability and competitiveness.

Comments are closed